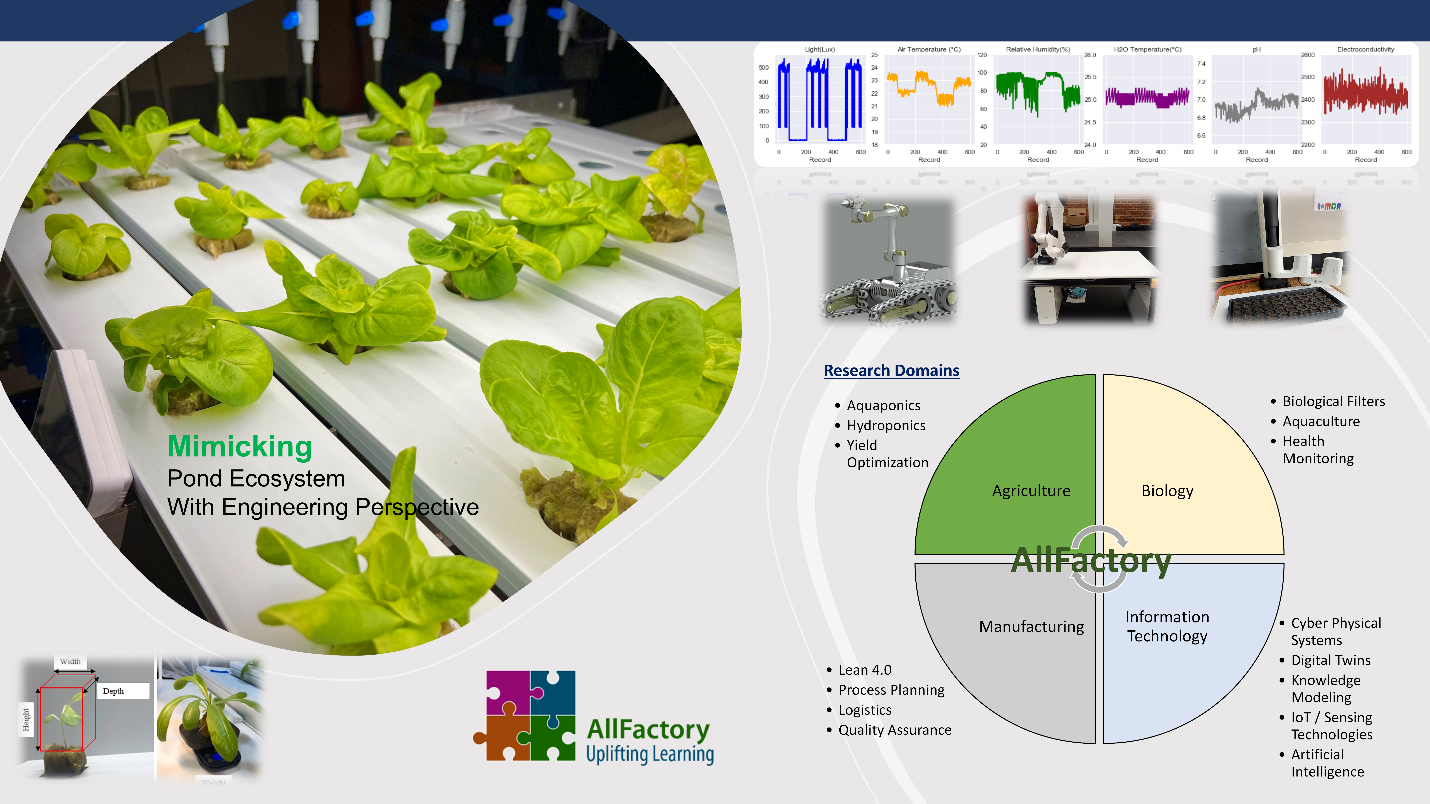

Research in Vertical Farming

Featured Research Projects

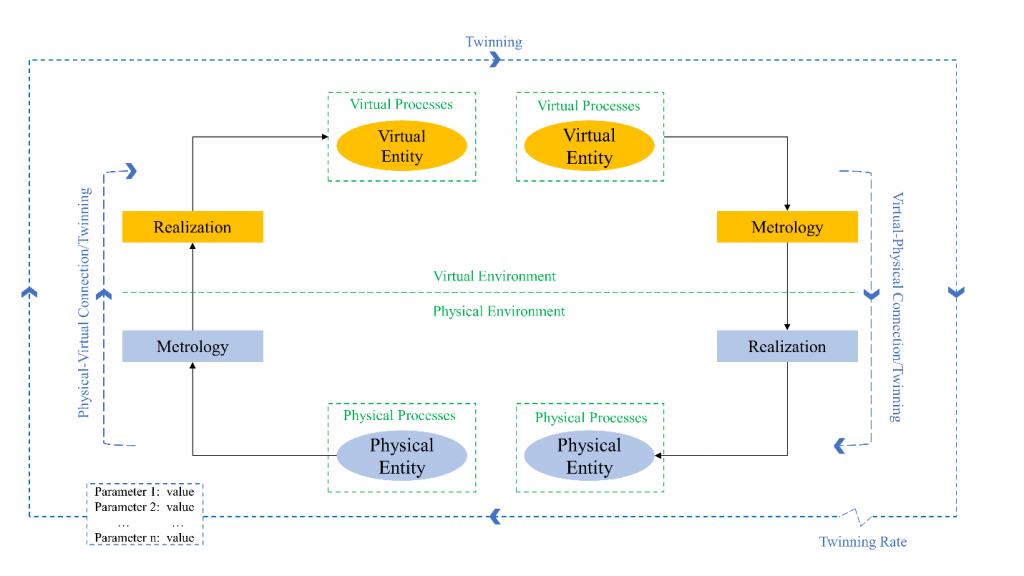

1) Digital Twin and Cyber-Physical System in Aquaponics:

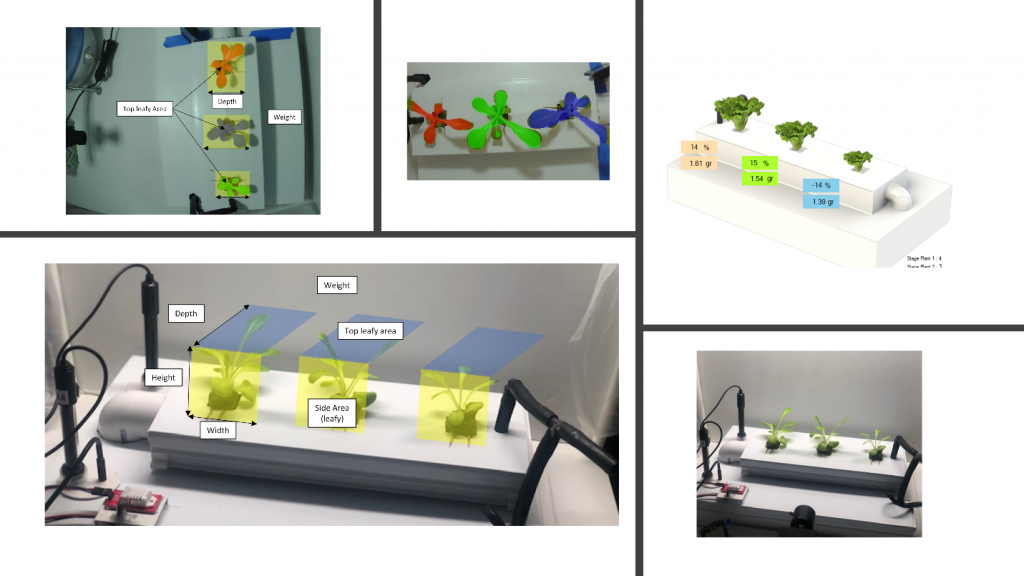

2) Quality control and computer vision applications in vertical farming

The lack of intelligent real-time approaches to monitor and track plant growth is hindering the transition of aquaponic systems towards automation and commercialization. Computer vision can promote further contributions to smart applications in aquaponics; therefore, a methodology is proposed to measure the growth rate and fresh weight of crops in multi-instance setups in real-time. The proposed system uses image-processing techniques, deep learning, and regression analysis to estimate the size of the crops as they grow using image segmentation. Then, a correlation between the size of the crops and their fresh weight is modelled. For common little gem romaine lettuce, the size of crops and fresh weight is estimated with an overall error of 30 mm (18.7%) and 0.5 g (8.3%), respectively.

3) Robotics in Agriculture:

Today’s advancements in Robotics, Computational Intelligence, Information Technologies and Hydroponics allow for very advanced and automated agriculture. This project aims to leverage all these advancements to bring about the next generation of farming and other agricultural equipment. We envision tomorrow’s companies using our framework like John Deere or New Holland, which built their empire on top of the Internal Combustion Engine.

As humanity ventures forward, agriculture will advance along with it. We are setting the stage for the second agricultural revolution, where food production is highly automated and requires little to no human supervision.